All Products

-

Aluminum Strip Coil

-

Color Coated Aluminum Coil

-

Aluminum Foil Roll

-

Aluminum Sheet Plate

-

Aluminum Circle Disc

-

Aluminum Foil Laminated Polyester Film

-

Aluminum Checkered Plate

-

Aluminum Diamond Plate Sheet

-

Embossed Aluminum Sheet

-

Anodized Aluminum Sheet

-

Mirror Aluminum Sheet

-

Aluminum Foil Container

-

Aluminum Foil Lunch Box

-

Disposable BBQ Grill

-

MartinThe first time we cooperated with Yongsheng Aluminum, we found it very easy, because the delivery time of the goods was very fast, and the business manager was also very professional. He helped me solve some technical problems. The goods were received on 2021.1.20 and the quality of the goods very good!

MartinThe first time we cooperated with Yongsheng Aluminum, we found it very easy, because the delivery time of the goods was very fast, and the business manager was also very professional. He helped me solve some technical problems. The goods were received on 2021.1.20 and the quality of the goods very good! -

Alice SuOur company and Yongsheng Aluminum have been cooperating for nearly three years. We have visited the factory, Yongsheng is a professional aluminum material supplier, we have been purchasing aluminum strips in their factory, and will maintain long-term cooperation.

Alice SuOur company and Yongsheng Aluminum have been cooperating for nearly three years. We have visited the factory, Yongsheng is a professional aluminum material supplier, we have been purchasing aluminum strips in their factory, and will maintain long-term cooperation. -

ZoeyWe purchase aluminum circle from Yongsheng Aluminum and ship them to Ghana. We have maintained such a cooperative relationship for two years, and we have to ship every month. In the process of cooperation, every link is very efficient, and the account manager will help us solve problems quickly. We are very happy to find a reliable supplier.

ZoeyWe purchase aluminum circle from Yongsheng Aluminum and ship them to Ghana. We have maintained such a cooperative relationship for two years, and we have to ship every month. In the process of cooperation, every link is very efficient, and the account manager will help us solve problems quickly. We are very happy to find a reliable supplier. -

Amin MazlumWe have purchased a total of nearly 500 tons of embossed color aluminum coils from Yongsheng Aluminum. The quality has been stable and the delivery time is fast. My customers are very satisfied with my products. We will continue to cooperate with Yongsheng Aluminum.

Amin MazlumWe have purchased a total of nearly 500 tons of embossed color aluminum coils from Yongsheng Aluminum. The quality has been stable and the delivery time is fast. My customers are very satisfied with my products. We will continue to cooperate with Yongsheng Aluminum.

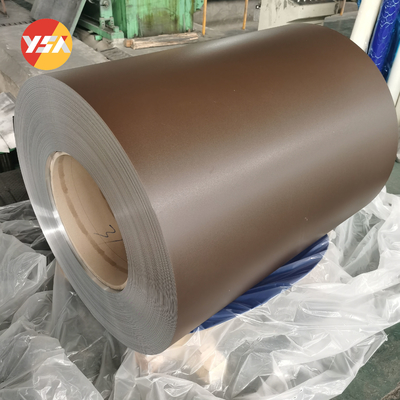

3003 3004 3005 Durable Color Coated Aluminum Coil Roll For Gutter Coil

| Place of Origin | Henan Province, China |

|---|---|

| Brand Name | YONGSHENG |

| Certification | SO,RoHS,MSDS,MTC |

| Model Number | 1000 3000 series |

| Minimum Order Quantity | 5 Ton |

| Price | 2950-3150 USD/Ton |

| Packaging Details | Standard Sea-worthy Packing |

| Delivery Time | 7-25 days after order confirmation |

| Payment Terms | L/C, D/A, D/P, T/T |

| Supply Ability | 5000 Tons per month |

Product Details

| Alloy | 1050, 1060, 1100, 3003, 3004, 3105, Etc. | Temper | O-H112 |

|---|---|---|---|

| Thickness | 0.2-3mm | Width | 10mm-1600mm, Can Be Divided Into Strips |

| Tolerance | ±1% | Surface Treatment | PVDF Coating , PE Coating Etc. |

| Coating Thickness | PE≥18 μm, PVDF≥25 μm | Color | Silver,bronze,black,gold,blue,grey,bright,etc |

| Packing | Export Seaworthy Wooden Pallet | Sample | Free |

| Highlight | color coated aluminum gutter coil,durable aluminum coil roll,3003 aluminum coil for gutters |

||

Product Description

3003 3004 3005 Durable Color Coated Aluminum Coil Roll for Gutter Coil

The most commonly used and ideal aluminum alloys for manufacturing gutter coils are AA3003, AA3004 and AA3005. Among them, AA3003 is the "gold standard" and the primary choice in this field. AA3003 is a typical heat-treatment-resistant aluminum-manganese alloy with composition approximately: manganese (Mn): 1.0 - 1.5%, copper (Cu): 0.05 - 0.20%, aluminum (Al): the remainder.

Material Comparison for Gutter Coil Manufacturing

| Characteristics | AA3003 Aluminum | Galvanized Steel | PVC Plastic | Copper |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (double protection) | Moderate (easily rusted at the cut) | Good (but prone to aging and brittleness) | Excellent (forms green copper oxide) |

| Life Expectancy | Extremely long (40+ years) | Medium | Medium | Extremely long |

| Weight | Light | Heavy | Light | Heavy |

| Cost | Medium (initial cost) | Low (initial cost) | Low (initial cost) | Extremely high |

| Life Cycle Cost | Low (no maintenance required) | High (requires painting maintenance) | Medium (requires replacement) | High |

| Aesthetics and Design | Abundant | Limited | Limited | Classic but Singular |

| Environmental Protection | High (can be infinitely recycled) | Medium | Medium | High |

From the comparison above, color-coated aluminum sheets represent the optimal choice for downpipe systems, combining superior material properties, performance, and economic benefits.

Materials Science & Corrosion Resistance

This is the primary reason why color-coated aluminum is used for downspouts:

- Natural corrosion resistance: Aluminum forms a dense oxide passivation film when exposed to air, preventing further contact with water and oxygen

- Dual protection coating: Physical barrier and chemical inertness provide complete isolation from water, acid rain, and pollutants

- Optimal alloy selection: Manganese-based alloys (3003, 3004, 3005) maintain excellent corrosion resistance while offering good formability

Surface Treatment & Aesthetics

Downspouts are important visual components that complement building facades:

- Extensive color options: Available in any RAL color range with wood-grain and stone imitation effects

- Long-lasting color retention: High-performance coatings resist UV degradation, maintaining brightness for decades

- Consistent coating quality: Automated roller coating ensures uniform thickness and color consistency

Mechanical Properties & Workability

Gutter coils require specific mechanical properties for roll forming:

- Excellent formability: Alloys in appropriate tempering states (H14, H24) can be bent into complex shapes without cracking

- Superior strength-to-weight ratio: Lightweight design reduces installation labor and structural load requirements

- Flexibility: Withstands slight collisions and thermal expansion without permanent deformation

Service Life & Life-Cycle Cost

Color-coated aluminum downspouts offer significant economic advantages:

- Extended service life: PVDF-coated systems can last over 40 years with no maintenance required

- Low total cost of ownership: Minimal maintenance and replacement costs make it the most cost-effective long-term solution

Environmental Sustainability

Modern building materials increasingly emphasize environmental attributes:

- 100% recyclable: Aluminum can be infinitely recycled using only 5% of the energy required for new production

- Pollution-free operation: Rainwater runoff contains no contaminants, making it environmentally safe

Product Images

Recommended Products