All Products

-

Aluminum Strip Coil

-

Color Coated Aluminum Coil

-

Aluminum Foil Roll

-

Aluminum Sheet Plate

-

Aluminum Circle Disc

-

Aluminum Foil Laminated Polyester Film

-

Aluminum Checkered Plate

-

Aluminum Diamond Plate Sheet

-

Embossed Aluminum Sheet

-

Anodized Aluminum Sheet

-

Mirror Aluminum Sheet

-

Aluminum Foil Container

-

Aluminum Foil Lunch Box

-

Disposable BBQ Grill

-

MartinThe first time we cooperated with Yongsheng Aluminum, we found it very easy, because the delivery time of the goods was very fast, and the business manager was also very professional. He helped me solve some technical problems. The goods were received on 2021.1.20 and the quality of the goods very good!

MartinThe first time we cooperated with Yongsheng Aluminum, we found it very easy, because the delivery time of the goods was very fast, and the business manager was also very professional. He helped me solve some technical problems. The goods were received on 2021.1.20 and the quality of the goods very good! -

Alice SuOur company and Yongsheng Aluminum have been cooperating for nearly three years. We have visited the factory, Yongsheng is a professional aluminum material supplier, we have been purchasing aluminum strips in their factory, and will maintain long-term cooperation.

Alice SuOur company and Yongsheng Aluminum have been cooperating for nearly three years. We have visited the factory, Yongsheng is a professional aluminum material supplier, we have been purchasing aluminum strips in their factory, and will maintain long-term cooperation. -

ZoeyWe purchase aluminum circle from Yongsheng Aluminum and ship them to Ghana. We have maintained such a cooperative relationship for two years, and we have to ship every month. In the process of cooperation, every link is very efficient, and the account manager will help us solve problems quickly. We are very happy to find a reliable supplier.

ZoeyWe purchase aluminum circle from Yongsheng Aluminum and ship them to Ghana. We have maintained such a cooperative relationship for two years, and we have to ship every month. In the process of cooperation, every link is very efficient, and the account manager will help us solve problems quickly. We are very happy to find a reliable supplier. -

Amin MazlumWe have purchased a total of nearly 500 tons of embossed color aluminum coils from Yongsheng Aluminum. The quality has been stable and the delivery time is fast. My customers are very satisfied with my products. We will continue to cooperate with Yongsheng Aluminum.

Amin MazlumWe have purchased a total of nearly 500 tons of embossed color aluminum coils from Yongsheng Aluminum. The quality has been stable and the delivery time is fast. My customers are very satisfied with my products. We will continue to cooperate with Yongsheng Aluminum.

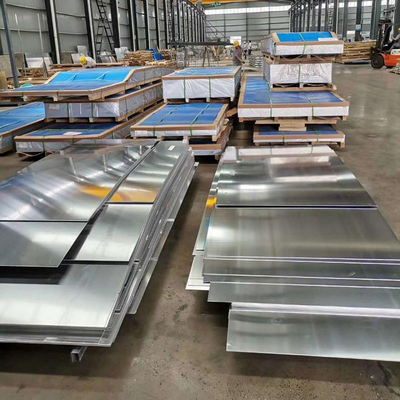

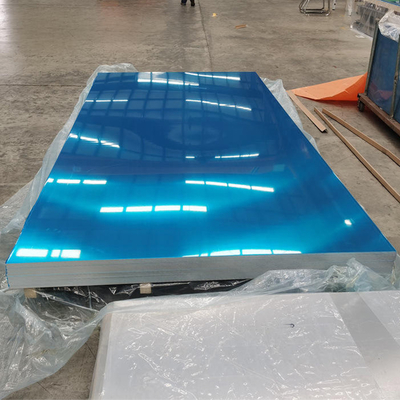

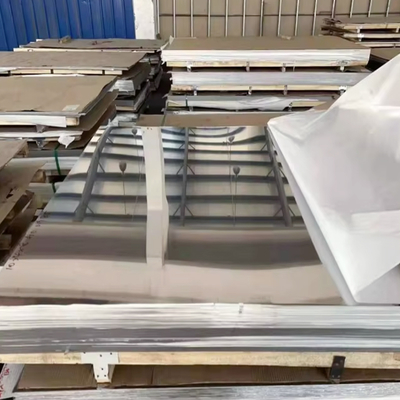

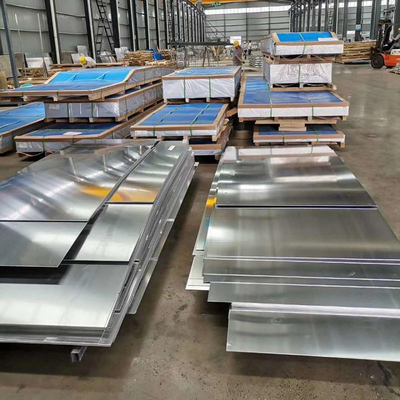

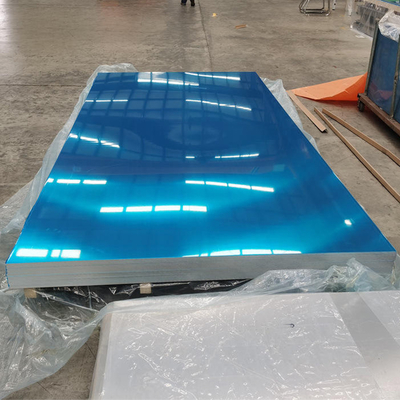

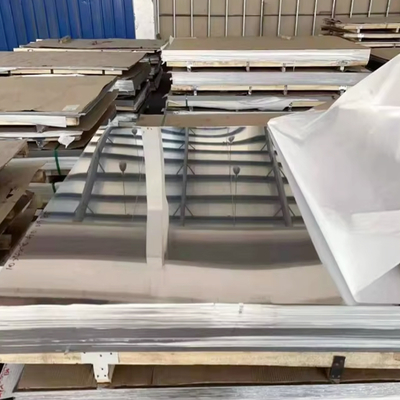

1100 3003 5052 6061 7075 Aluminum Plate Aluminum Sheet

| Place of Origin | Henan Province, China |

|---|---|

| Brand Name | YONGSHENG |

| Certification | ISO, RoHS |

| Model Number | 1000 3000 5000 Series |

| Minimum Order Quantity | 1 Ton |

| Price | 2850-3250 USD/Ton |

| Packaging Details | Standard Sea-worthy Packing |

| Delivery Time | 7-25 days after order confirmation |

| Payment Terms | L/C, D/A, D/P, T/T |

| Supply Ability | 5000 Tons per month |

Product Details

| Keyword | Aluminum Sheet | Material | Aluminum Alloy Metal |

|---|---|---|---|

| Temper | O-H112 | Width | 10-2000mm |

| Thickness | 0.15-200mm Customized | Shape | Flat Plate |

| Surface Treatment | Mill Finish | Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

| Port | QingDao, ShangHai, TianJin | Sample | Free |

| Highlight | 6061 aluminum plate with warranty,5052 aluminum sheet for fabrication,7075 aluminum plate high strength |

||

Product Description

Aluminum Plate & Sheet Products

We specialize in 1100, 3003, 5052, 6061, and 7075 aluminum plates and sheets, offering customized solutions for various industrial applications.

Product Specifications

| Attribute | Value |

|---|---|

| Keyword | Aluminum Plate |

| Temper | O-H112, T3-T8, T351-T851 |

| Thickness | 0.15-600mm Customized |

| Width | 10-2600mm Customized |

| Length | As customer's requirements |

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

| Shape | Flat Plate |

| Surface | Silver, Mill Finish |

| Edge | Excellent surface quality |

| Standard | GB/T3880; ASTM B209 |

| Packing | Standard Sea-worthy Packing |

| Delivery time | 20-30 days |

| MOQ | 2 ton |

| Port | QingDao, ShangHai, TianJin (any port in China) |

| Sample | Free |

Key Features

- Easy installation

- High strength

- Low in costs

- Durable

- Nice appearance

- Anti oxidation

Applications

- Building and construction

- Decoration

- Curtain wall

- Shelter

- Oil tank

- Mould

Remark: Specific requirements for alloy grade, temper, or specification can be discussed at your request.

The 1000 series, 3000 series, and 5000 series are the most common and widely used types of aluminum plates. They have significantly different properties due to variations in their main alloying elements.

1000 Series Aluminum Sheets (Pure Aluminum Sheets)

Composition and Properties

This series consists of industrial pure aluminum with an aluminum content of at least 99.00%. It contains no deliberately added alloy elements, retaining the essential properties of aluminum.

Advantages

- Excellent electrical and thermal conductivity, very close to pure aluminum

- Superior corrosion resistance with dense Al₂O₃ protective film formation

- Excellent plasticity for further processing

- Soft texture with shiny appearance

Disadvantages

Lowest strength and hardness among aluminum alloys, prone to deformation, and not suitable for structural components.

Common Grades

- 1060: Contains over 99.6% aluminum, known as "mature aluminum" with balanced purity and processing performance

- 1050: Contains over 99.5% aluminum, with performance similar to 1060

- 1100: Contains over 99.0% aluminum with slightly higher strength but slightly poorer corrosion resistance

Typical Applications

- Conductive materials: Transformer coils, capacitors, busbars, and cables

- Heat-conducting materials: Heat sinks, heat exchangers, cookware, lamps

- Deep drawing products: Aluminum bottles, chemical storage tanks, utensils, signs, bottle caps

- Decorative materials: Reflective plates for lighting, interior decorative items, signboards

- Building applications: Building panels and rolling shutters with low strength requirements

3000 Series Aluminum Plates (Aluminum-Manganese Alloy)

Composition and Properties

The main alloying element is manganese (Mn), typically ranging from 1.0% to 1.5%.

Advantages

- Approximately 20% higher strength than 1000 series

- Excellent corrosion resistance with good processing properties

- Rust-proof aluminum with stable performance at high temperatures

Disadvantages

Not suitable for high-stress structural components despite increased strength.

Common Grades

- 3003: Classic aluminum-manganese alloy with balanced strength and corrosion resistance

- 3004/3005: Higher magnesium content for increased strength, ideal for tank bodies

Typical Applications

- Kitchenware and household appliances: Refrigerator evaporators, air conditioner condensers, microwave ovens

- Can material: Beverage cans, chemical product containers, tanker skins

- Construction: Roofs, ceilings, walls, blinds, awnings, garage doors

- Vehicle interiors: Bus and truck interior panels, container panels

- Sheet metal processing: Cases and exteriors requiring good formability and corrosion resistance

5000 Series Aluminum Sheets (Aluminum-Magnesium Alloy)

Composition and Properties

The main alloying element is magnesium (Mg), with content ranging from 3% to 5%.

Advantages

- High strength - up to twice or more than 1000 series aluminum plates

- Excellent corrosion resistance, particularly in marine and chemical environments

- Superior weldability, making it ideal for ships and marine engineering

- Good processing performance

Disadvantages

Higher cost compared to 1000 and 3000 series. Stress corrosion cracking tendency controlled through heat treatment.

Common Grades

- 5052: Medium magnesium content with optimal balance of strength, formability, and corrosion resistance

- 5083: High magnesium content with superior strength for welding structural components

- 5754: Similar to 5083, commonly used in automotive and transportation applications

Typical Applications

- Maritime and shipping: Ship plates, decks, cabin partitions, offshore platforms

- Vehicle manufacturing: Car doors, floor plates, fuel tanks, tanker tanks, rail car bodies

- Pressure vessels: Chemical tanks, oil pipelines, LNG storage tanks

- Military applications: Armor plates, tank tracks, military speedboats

- High-end electronics: Mobile phone frames, laptop computer shells

- Building formwork: High-strength, corrosion-resistant reusable formwork

Products Detail

Products Application

Recommended Products