-

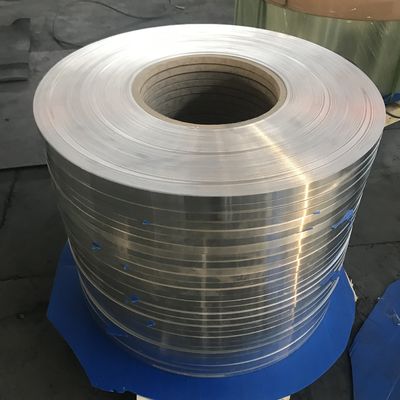

Aluminum Strip Coil

-

Color Coated Aluminum Coil

-

Aluminum Foil Roll

-

Aluminum Sheet Plate

-

Aluminum Circle Disc

-

Aluminum Foil Laminated Polyester Film

-

Aluminum Checkered Plate

-

Aluminum Diamond Plate Sheet

-

Embossed Aluminum Sheet

-

Anodized Aluminum Sheet

-

Mirror Aluminum Sheet

-

Aluminum Foil Container

-

Aluminum Foil Lunch Box

-

Disposable BBQ Grill

-

MartinThe first time we cooperated with Yongsheng Aluminum, we found it very easy, because the delivery time of the goods was very fast, and the business manager was also very professional. He helped me solve some technical problems. The goods were received on 2021.1.20 and the quality of the goods very good!

MartinThe first time we cooperated with Yongsheng Aluminum, we found it very easy, because the delivery time of the goods was very fast, and the business manager was also very professional. He helped me solve some technical problems. The goods were received on 2021.1.20 and the quality of the goods very good! -

Alice SuOur company and Yongsheng Aluminum have been cooperating for nearly three years. We have visited the factory, Yongsheng is a professional aluminum material supplier, we have been purchasing aluminum strips in their factory, and will maintain long-term cooperation.

Alice SuOur company and Yongsheng Aluminum have been cooperating for nearly three years. We have visited the factory, Yongsheng is a professional aluminum material supplier, we have been purchasing aluminum strips in their factory, and will maintain long-term cooperation. -

ZoeyWe purchase aluminum circle from Yongsheng Aluminum and ship them to Ghana. We have maintained such a cooperative relationship for two years, and we have to ship every month. In the process of cooperation, every link is very efficient, and the account manager will help us solve problems quickly. We are very happy to find a reliable supplier.

ZoeyWe purchase aluminum circle from Yongsheng Aluminum and ship them to Ghana. We have maintained such a cooperative relationship for two years, and we have to ship every month. In the process of cooperation, every link is very efficient, and the account manager will help us solve problems quickly. We are very happy to find a reliable supplier. -

Amin MazlumWe have purchased a total of nearly 500 tons of embossed color aluminum coils from Yongsheng Aluminum. The quality has been stable and the delivery time is fast. My customers are very satisfied with my products. We will continue to cooperate with Yongsheng Aluminum.

Amin MazlumWe have purchased a total of nearly 500 tons of embossed color aluminum coils from Yongsheng Aluminum. The quality has been stable and the delivery time is fast. My customers are very satisfied with my products. We will continue to cooperate with Yongsheng Aluminum.

19mm 50mm 1000 Series Thin Aluminum Strips 1050

| Product Name | Aluminum Strip Coil | Place Of Origin | China |

|---|---|---|---|

| Brand | Yongsheng Aluminum Industry Co., Ltd. | Alloy/Grade | 1000series-8000series |

| Temper | O - H112 , T3 - T8 , T351 - T851 | Tolerances | As Per Your Requirements |

| Thickness | 0.13mm - 5.0mm | Width | 3mm-2600mm |

| Length | As Per Your Requirements | Coil ID | As Per Your Requirements |

| Highlight | 50mm Thin Aluminum Strips,Thin Aluminum Strips 1050,19mm aluminium 1000 series |

||

1050 aluminum strip is a commercially pure wrought 1000 series alloy with 99.5% aluminum purity, offering excellent ductility, plasticity, corrosion resistance, and high electrical and thermal conductivity.

- Excellent processability for turning, milling, boring, and planing operations

- High electrical conductivity: 62% IACS at 20℃

- Superior thermal conductivity: 231W/(m•℃) at 20℃

- Excellent anodic oxidation effect and high reflectivity

- Non-heat treatment alloy with low strength

- Suitable for contact welding and gas welding

Ideal for applications requiring high corrosion resistance and formability with low strength requirements:

- Chemical industry containers

- Lithium battery soft connections and pole lug materials

- Explosion proof valves and PS plate bases

- Signage, pallets, lighting fixtures, and reflection plates

- Heat dissipation plates and insulation materials

- CTP plates and various industrial components

| Alloy | State | Thickness (mm) | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|---|---|

| 1060 (1050) | 0 | > 0.2-0.5 | 60-100 | ≥ 15 | ≥ 20 | 20-30 |

| 0 | > 0.5-1.0 | 60-100 | ≥ 30 | ≥ 20 | 20-30 | |

| 0 | > 1.0-4.0 | 60-100 | ≥ 35 | ≥ 20 | 20-30 | |

| H22 | > 0.2-0.5 | 80-120 | ≥ 60 | ≥ 12 | 30-40 | |

| H22 | > 0.5-1.0 | 80-120 | ≥ 60 | ≥ 15 | 30-40 |

- Alloy/Grade: 1000-8000 Series

- Temper: O-H112, T3-T8, T351-T851

- Thickness: 0.13mm - 6.5mm

- Width: 3mm - 2600mm

- Length: Customized to requirements

- Color: Silver

- Conductivity: ≥61.5% IACS

- Elongation: > 23%

- Surface Treatment: Mill Finish, Coated, Powder Coated, Anodized, Polished Mirror, Embossed

- MOQ: 1 ton

- Delivery Time: 7-30 days after order confirmation

- Pure aluminum strip

- Transformer aluminum strip

- Super hard aluminum strip

- All soft aluminum strip

- Semi hard aluminum strip

- Rust proof aluminum strip

Henan Yongsheng Aluminum Co., Ltd. is located in Gongyi City Industrial Cluster Area, Henan Province. The factory specializes in aluminum products including Aluminum Strip, Color Aluminum, Aluminum Sheet, Aluminum Coil, Pressed Aluminum Product, Embossed Aluminum, and non-slip aluminum Sheet. With 100,000 square meters of facility space, 476 employees, and advanced production lines, we achieve an annual output exceeding 200,000 tons, with exports accounting for over 40% of production.

- We provide samples via TNT, DHL, FEDEX, EMS, UPS or direct to your warehouse

- Pre-production samples provided before mass production

- Final inspection conducted before shipment

Our standard production time is 7-15 working days.

Shipping costs depend on order size, weight, and shipping method selected.

We maintain 10,000 tons of stock in various sizes. Please inform us of your specific requirements for current stock details.

- 20 years of experience in the aluminum industry

- Source manufacturer with leading equipment and skilled team

- Competitive pricing, fast delivery, and excellent quality

- Professional technical solutions and support

- Delivery Terms: FOB, CFR, CIF, EXW, CIP, CPT, DDP, DDU

- Payment Currency: USD, EUR, HKD, GBP, CNY

- Payment Methods: T/T, L/C, D/P D/A, Credit Card, PayPal, Western Union, Cash, Escrow

- Languages: English, Chinese, Spanish, Japanese, Portuguese, Korean

Packing Details:

- 20MT capacity in 20-foot container (recommended for cost efficiency)

- Three-layer protection: thick fiber, foam, plastic with sufficient drying agent

- Suitable for long-distance sea transportation

- Wooden or steel pallets available per customer request

- External packaging uses wooden boxes

- Container securing to prevent damage during transit

- 24 wooden boxes per 20ft container

Reliable quality, reasonable pricing, and prompt delivery are guaranteed.

Tell us what you need, and we will try our best to accommodate your requirements.